ATR300S | Plate Separating Router

National technology with industrial precision for separating electronic boards

ROUTER ATR300S

- Model: ATR300S;

- Simple plate separator router;

- Indicated for low and medium production;

- High production performance and high process performance;

- National Production

Description:

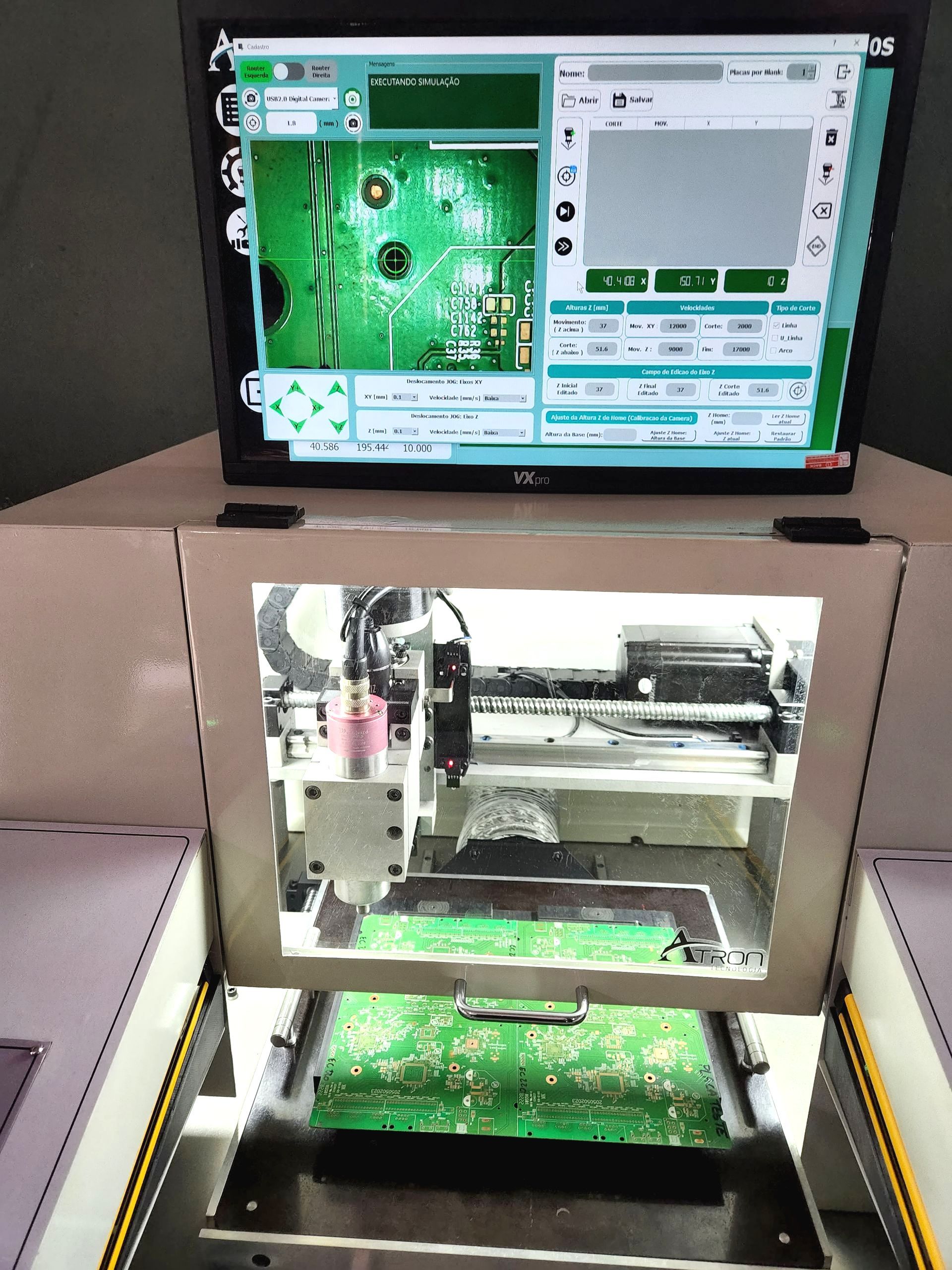

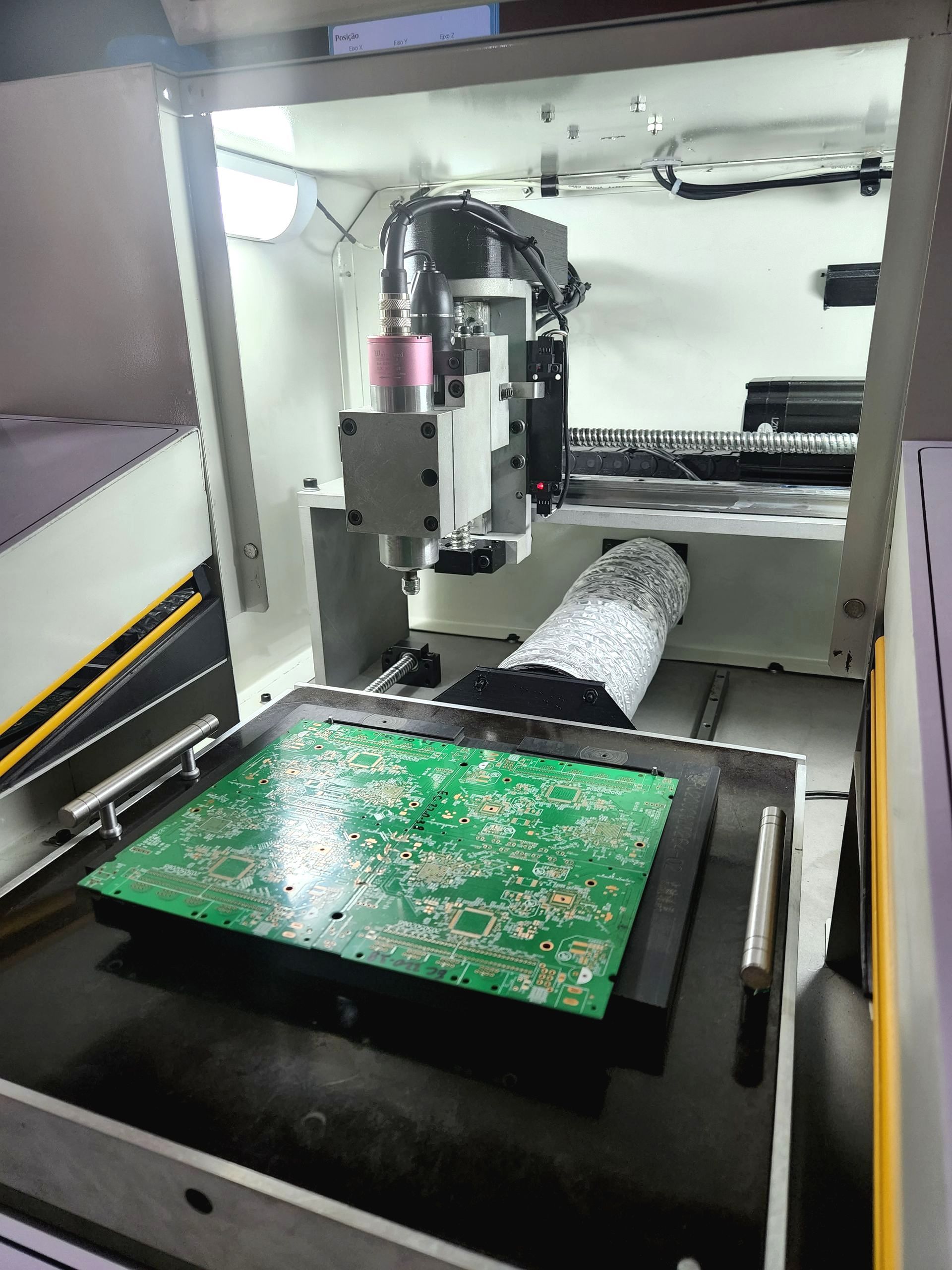

Equipment designed for the agile depaneling of plates with a high-resolution camera that facilitates programming, precision servo motors that enable excellent repeatability and low scrap. It has a silent and dedicated exhaust system to reduce plate waste.

It contains a very intuitive interface with easy operation, allows the creation and editing of cutting points, automatic leveling of the Z axis through the probe sensor, reducing setup time, has an IIot (Industrial Internet of Things) system that enables real-time monitoring of the equipment, assisting in the production process.

Features

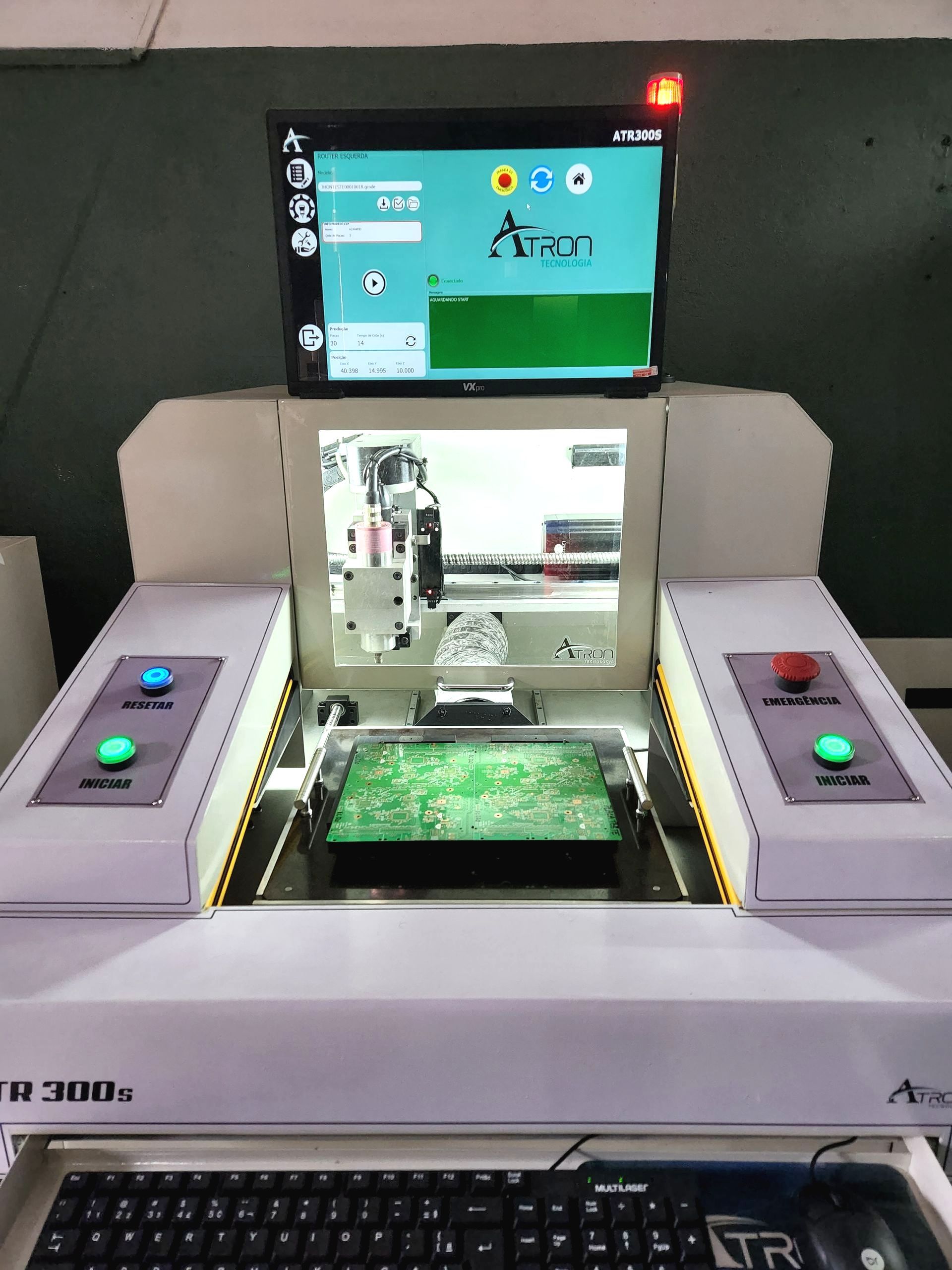

Meets regulatory standards NR10 and NR12;

Light curtain - protection during operation;

• Emergency pushbutton;

• Light curtain monitoring safety relay;

ESD system for static control.

ASCE - Atron Axis Control System

With a user-friendly human-machine interface and a CCD camera, it becomes easy and time-efficient to program the cutting points. The user can easily define the cutting marking points through the camera and the virtual environment for the points table. The data in the registration form is easily visible and editable.

Datasheet

Model: ATR300S Dimensions: 740mm(W) X 840mm(D) X 1800mm(H) Equipment Weight: 240kg Heads: 01 Bases: 01 Spindle: Electric Air Cooled Spindle RPM: 60,000 rpm Cutting area table 01: 300mm X 300mm Cutting area table 02: 0 Transmission System: Ballscrew Spindle Transmission System: Linear Guide Actuator System: Easy Servo Driving Speed (MAX): 300 mm/s Cutting Speed (MAX): 50 mm/s Cutting Accuracy: ± 0.1 mm Positioning Accuracy: ± 0.1 mm Positioning Repeatability: ± 0.1 mm PCB Thickness: 0.5 ~ 2 mm Component Height: Top Side 15 mm / Bottom Side 45 mm Control System: Atron System integrated with PLC Monitor: 15" Exhaust: 1hp Motor

GUARANTEE

A) Equipment:

- Full manufacturer's warranty for a period of 12 (twelve) months after the date of shipment.

- Shipping and returning parts under warranty to the manufacturer are the customer's responsibility.

- Defects caused by improper use are excluded from the warranty.

- Full parts supply warranty for 10 (ten) years.

B) Labor:

- 12 (twelve) months after the date of shipment.

- Defects caused by improper use are excluded from the warranty.

- For equipment installed outside the city of Manaus, travel and accommodation expenses for ATRON's technical personnel, incurred during equipment installation, training sessions, and technical assistance calls, will be the customer's responsibility.

Service Limitations:

Technical assistance within the service warranty period will be free of charge during business hours — MON to FRI, from 8:00 a.m. to 5:00 p.m.

Service requested outside of business hours will be charged per actual working hour, regardless of the call condition.

Coverage:

All parts and components subject to natural wear and tear, or caused by failure or lack of preventive maintenance and conservation, or by operational errors, or by intervention from unauthorized or unqualified third parties, are considered "out of warranty".

The group of wear-and-tear parts includes all movement, friction, and constantly driven units under the direct influence of external supply sources, such as compressed air, vacuum, and water. The most common include: chains, guides, pulleys, sprockets, belts, bearings, bushings, air filters, general filters, lenses, nozzles, limit switches, ejector valves, solenoid valves, pneumatic pistons, among other parts proven to be subject to movement and wear.

For services involving this group, technical hours employed in repair or replacement will be charged separately according to the standard technical hour rate in effect at the time.

Installation:

Installation will be carried out by an ATRON technician at no additional cost to the customer. However, for equipment installed outside the city of Manaus, travel, food, and accommodation expenses will be the customer’s responsibility.

See more details of

Router ATR300S

Presentation of the PCB Depanelizing Router machine, showing the main features, details and demonstrations of its performance.