ATC1200DL | Conveyor Link Dual Lane

High performance and full integration with SMT lines

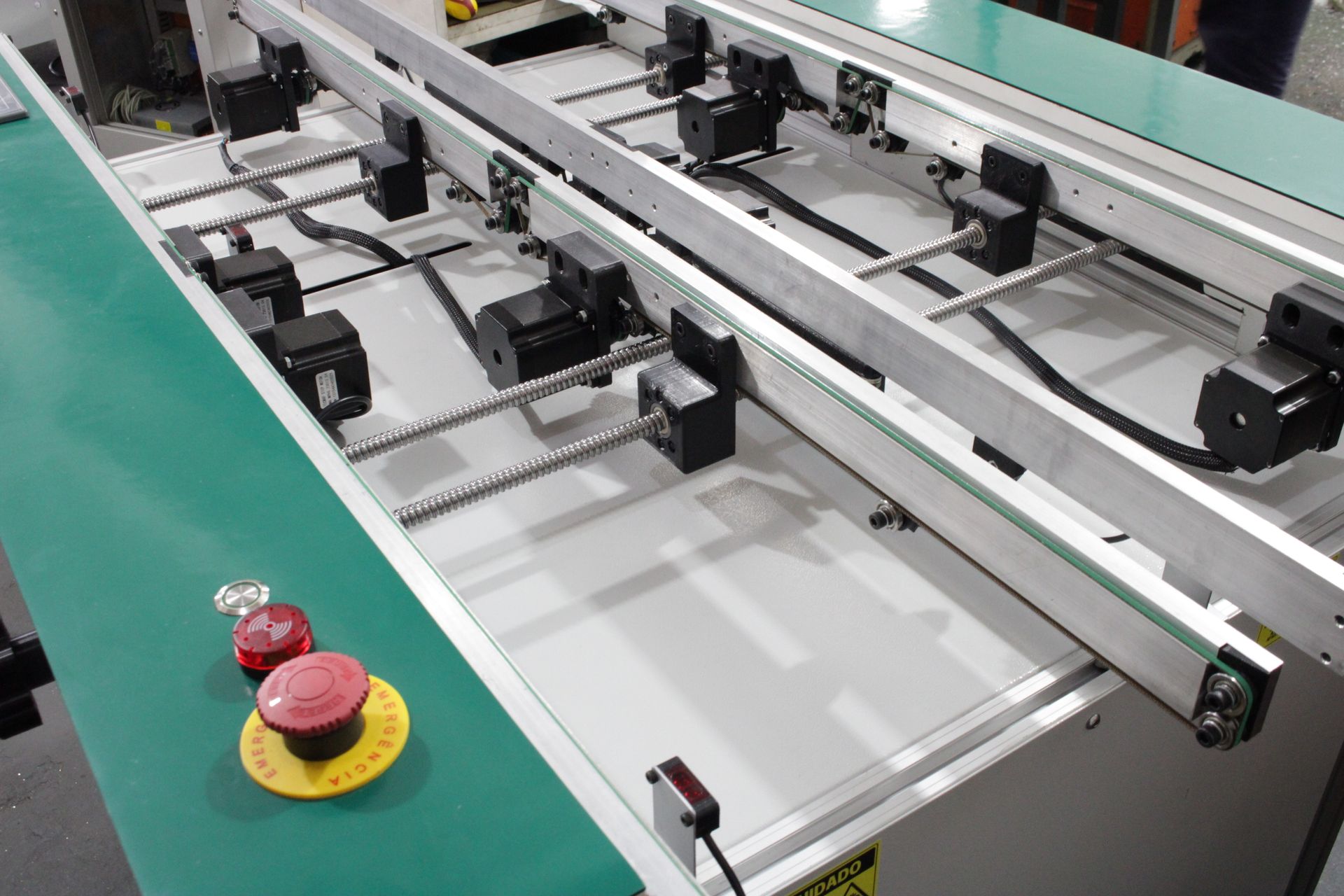

ATC1200DL - CONVEYOR DUAL LANE

The ATC1200DL Conveyor is a high-performance national equipment developed for electronic assembly lines (SMT). It offers robustness, intuitive control via PLC/HMI and compliance with NR12 safety standards, ideal for medium and high production.

Main Benefits

✔️ Compatible with SMEMA

✔️ Suitable for medium and high production

✔️ National production with direct technical support

✔️ Reinforced enclosure and safety

________________________________________

Applications and Indications

- Electronic production lines

- Integration with pick-and-place machines

- Medium and high complexity SMT systems

- Industries that require traceability and operational safety

Datasheet

Structure and dimensions

- Dimensions: 1200mm (L) x 800mm (W) x 910mm (H)

- Frame: High-strength structural aluminum profile

- Fairing: Electrostatically painted steel plate

- Approximate weight: 60 kg

- Maximum Opening: 300 mm

- Width Adjustment: Manual by handwheel

- Feet: Adjustable leveling shoes

- Top Cover: Polycarbonate with safety lock

Conveyor System

- Type: Dual Lane

- Belt: 6mm ESD conductive belt

- Motors: Individual stepper motor per lane

- Sensors: Diffuse sensor with adjustable position

- Plate Detector (PCB): Included

- SMEMA Communication: Integrated for synchronization with SMT line

Control and Interface

- PLC: Programmable Logic Control with full monitoring

- HMI: Intuitive Human-Machine Interface

- Monitoring: LED indicators on the panel

- Hour meter: Included

Safety

- Top door sensor

- Lid safety relay

- Emergency button

- Monitored emergency relay

Power and Integration

- Power Supply: 220V / 60Hz

- Current: 3A

- Air Pressure: Not applicable (N/A)

Options on Request

- Custom dimensions

Guarantee

A) Equipment:

Full manufacturer's warranty for a period of 12 (twelve) months after the date of shipment.

Shipping and returning parts under warranty to the manufacturer are the customer's responsibility.

Defects caused by improper use are excluded from the warranty.

Full parts supply warranty for 10 (ten) years.

B) Labor:

12 (twelve) months after the date of shipment.

Defects caused by improper use are excluded from the warranty.

For equipment installed outside the city of Manaus, travel and accommodation expenses for ATRON's technical personnel, incurred during equipment installation, training sessions, and technical assistance calls, will be the customer's responsibility.

Service Limitations:

Technical assistance within the service warranty period will be free of charge during business hours — MON to FRI, from 8:00 a.m. to 5:00 p.m.

Service requeste outside of business hours will be charged per actual working hour, regardless of the call condition.

Coverage:

All parts and components subject to natural wear and tear, or caused by failure or lack of preventive maintenance and conservation, or by operational errors, or by intervention from unauthorized or unqualified third parties, are considered "out of warranty".

The group of wear-and-tear parts includes all movement, friction, and constantly driven units under the direct influence of external supply sources, such as compressed air, vacuum, and water. The most common include: chains, guides, pulleys, sprockets, belts, bearings, bushings, air filters, general filters, lenses, nozzles, limit switches, ejector valves, solenoid valves, pneumatic pistons, among other parts proven to be subject to movement and wear.

For services involving this group, technical hours employed in repair or replacement will be charged separately according to the standard technical hour rate in effect at the time.

Installation:

Installation will be carried out by an ATRON technician at no additional cost to the customer. However, for equipment installed outside the city of Manaus, travel, food, and accommodation expenses will be the customer’s responsibility.

See more details of

Conveyor Dual Lane ATC1200DL

Watch the video and see how the ATC1200DL Dual Lane Conveyor works. We present the equipment in operation so that you can learn about its structure, robust construction and mechanical performance — ideal for automation and industrial transport applications.